Attractive and eye catching package makes the difference on markets shelf.

De-palletizing and De-crating solutions. Palletizers, and palletizing isles, Shrink-wrapping machines, Craters, Wrap around case-packer machines, Sleeve packing machines, Handle applicators.

Filling & Packaging can offer all the solutions to accomplish all clients marketing needs, in term of quality, products, look and cost effectiveness. A wide range machineries and systems to pack cans, bottles, jars and any container and make it available for stock and transports safely and economically at any degree of automation and speed.

- Forte series:

A line of packaging, palletizing and de-palletizing machines to fit clients needs in term of speed and solutions. These advanced machines are strong carpentry built but clean and soft with packs and containers. Our flexible design and engineering technology allows our technicians to find the right solution to palletize, depalletize and pack containers of any shape at any speed. - Forte-DPA: Automatic and semi-automatic de-palletizers from 0,7 to 3 layers per minute

- Forte-PA: Automatic high spped palletizers from 4 to 4,5 layers per minute

- Forte-Arm: Advanced flexible anthropomorphous machine to palletize compose and move packs and arrange palletizing schema for any application at a speed of 8 cycles per minute.

- Flex series:

A line of packaging, palletizing and de-palletizing machines built in AISI 304. These advanced machines are suitable for long period lasting in aggressive environments. Perfectly suitable for food and beverage application and anywhere rust is to be avoid for food safety or working environment preservation. State of the art technology and high value iron material characterize the Flex line to maximize return on clients capital expenditure.- Flex-DeP: automatic and semi-automatic de-palletizers from 1 to 2 layers per minute.

- Flex-Cest and Flex-DeCest: automatic system to discharge full containers from crates after pasteurization. Filling & Packaging couple Flex-decest with Flex-cest for preparing full containers in crates before autoclaves and discharge them to feed palletizing islands

- Flex-DeBox: automatic machine to discharge crates and boxes from full or empty containers from420 to 2.700 cartons per hour.

- Flex-Estensa: series machines are suitable for automatic and semiautomatic wrapping of palletized bundles with stretch film.

- Flex-Erecta: automatic American carton box moulder from 720 to 2.250 cartons per hour.

- Flex-Inbox: automatic bottle and tin-can placer in preformed cartons from 420 to 2.700 cartons per hour.

- Flex-CloseBox: automatic or semi-automatic closing machine for American carton from 720 to 2.250 cartons per hour.

- Flex-ComBox: automatic multiple secondary packaging composer for cluster in boxes 420 to 1.000 cartons per hour.

- Shrink-wrapping machines:

Automatic machine to wrap film around primary packaging. Filling & Packaging

offers many kind of shrink wrapping machines from low to high speeds. Shrink-wrapping machines can be optionally integrated with try-formers

machine or systems. - Cluster wrap around case-packer machines:

No limit to design and packaging image with the multiple possibilities offered by

integrated machineries from Filling & Packaging. - Sleeve packing machines:

Automatic bottle and tin-can placer in preformed cartons from 420 to 2.700 cartons per hour. - Handle applicators:

To complete cluster packaging or any kind of shrink wrapped package Filling & Packaging is

able to offer on the market the most interesting and reliable handle applicator machines.For more information please contact sales@fillandpack.com

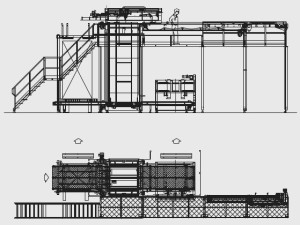

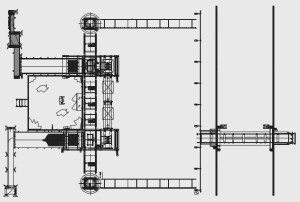

FORTE DPA

Automatic and semi-automatic de-palletizers from 0,7 to 3 layers per minute for bottles and cans.

Technical characteristics

| The machine includes:

|

go back to product list

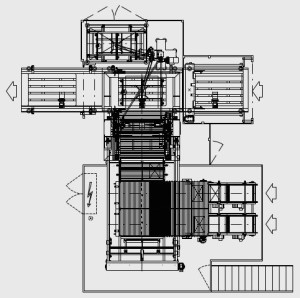

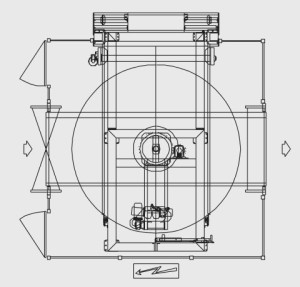

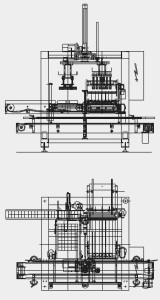

FORTE PA

FORTE PA series machines palletizes entire layers of carton/bundlers coming from the bottling lines through single or double row, with low or high level infeed. Automatic high speed palletizers up to 4,5 layers per minute.

Technical characteristics

| The machine includes:

|

go back to product list

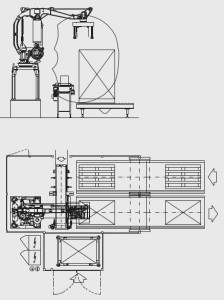

FORTE ARM

CLICKT TO ENLARGE

FORTE ARM series machines are suitable to palletize on pallet packages/cartons that come from packaging line

in single-row or multiple-row, at low or high level. FLEXROBOT can handle every type of product made of different materials and shape.

Technical characteristics

| The machine includes:

|

go back to product list

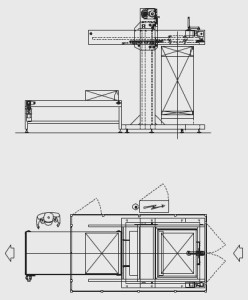

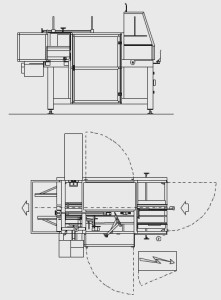

FLEX-DEP

FLEX-DEP series machines depalletize entire layers of bottles and tin-cans unloading them on height.

The machine is made of stainless steel to operate in particular corrosive environment and guarantee rust-less operations.

Technical characteristics

| The machine includes:

|

go back to product list

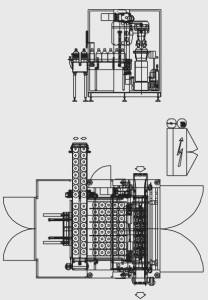

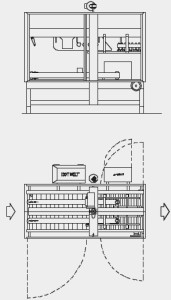

FLEX-CEST and FLEX-DECEST

FLEX-CEST and FLEX-DECEST is a special system for basket loading and unloading. The machines can be used for any tin-can or glass jars loading and unloading to feed and discharge sterilizing autoclaves.

The machine is made of stainless steel to operate in particular corrosive environment and guarantee rust-less operations. The series includes automatic and semi-automatic machines with speed from 2 to 6 layers per minute.

Technical characteristics

| The machine includes:

|

go back to product list

FLEX-DEBOX series machines

FLEX-DEBOX series machines are suitable for taking bottles out of crates and cartons and then placing them on

the packaging line. The machines are made of stainless steel to operate in particular corrosive environment and guarantee rust-less operations. The series includes fully automatic machines with speed from 420 to 2.700 cartons per hour.

Technical characteristics

| The machine includes:

|

go back to product list

ESTENSA

ESTENSA series machines are suitable for automatic and semiautomatic wrapping of palletized bundles with stretch film. The machines are made of heavy duty bent sheet steel and they dispose of reel-holder devices to regulate film pre-stretching and up/down speed. The automatic models include post-wrapping blocking and cutting devices and a motorized pallet roll-conveyor. The machines are optionally made of stainless steel to operate in particular corrosive environment and guarantee rust-less operations. The series includes fully automatic machines with speed from 20 to 60 pallets per hour.

Technical characteristics

| The machine includes:

|

go back to product list

FLEX-ERECTA

FLEX-ERECTA machines mould American carton type boxes by picking , moulding and closing cartons with adhesive tape or

hot melt glue. The machines are made of stainless steel to operate in particular corrosive environment and guarantee rust-less operations. The series includes fully automatic machines with speed from 720 to 2.700 cartons per hour.

Technical characteristics

| The machine includes:

|

go back to product list

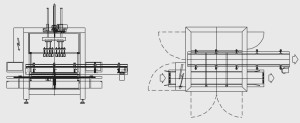

FLEX-INBOX SERIES

FLEX-INBOX SERIES are suitable machines for receiving and properly arranging bottles/tin-cans that arrive from

the filling line. They take and place containers in pre-formed cartons.The machines are made of stainless steel to operate in particular corrosive environment and guarantee rust-less operations. The series includes fully automatic machines with speed from 720 to 2.700 cartons per hour.

Technical characteristics

| The machine includes:

|

go back to product list

FLEX-CLOSEBOX

FLEX-CLOSEBOX series machines are suitable machines for closing of the upper part of the american carton boxes with hot melt glue or adhesive tape. This machine series includes fully automatic machines with speed from 720 to 2.250 cartons per hour.

Technical characteristics

| The machine includes:

|

go back to product list

FLEX-COMBOX

FLEX-COMBOX series machines are suitable machines for receiving and properly actuating different packing operations: object receiving carriers or bottles/tin-can arranging, separately or contemporary picking and placing of the product in pre-formed cartons. The machines are made of stainless steel to operate in particular corrosive environment and guarantee rust-less operations. The series includes fully automatic machines with speed from 420 to 1.000 cartons per hour.

Technical characteristics

| The machine includes:

|