Assistance is at first place in our commitments

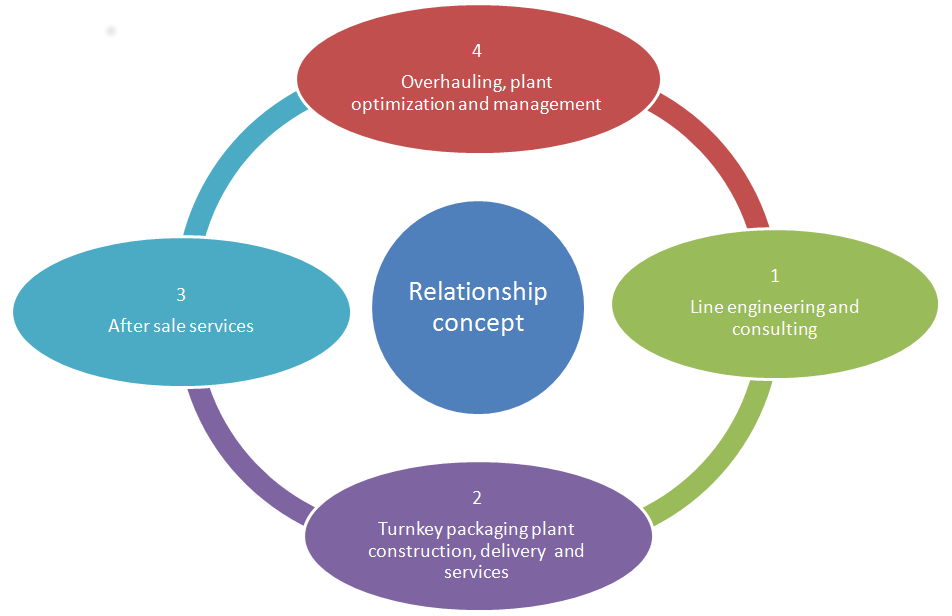

Filling & Packaging offers A to Z service. Our working tools are experience, competence, attention to customer needs, habit to work worldwide.

By complete service we mean helping the customer in his/her decision process, helping with the right packaging and machineries choices, with packaging accessories and the best design of the packaging line.

We scale satisfaction and goals achievement with the customer loyalty, obtained through after sale assistance. That’s a great added value for both parts.

The Filling & Packaging maintenance team follows a life-cycle approach, based on an integrated model from design to end-of-life, to support decision making about critical and high capital assets.

-

Line engineering and consulting

- Products, container and packaging consulting:

- Primary packaging

Our counseling on primary packaging starts from its production with preforms and caps production machineries and ends with the controlling and inspection units. We support the customer with the choice of the most appropriate container and related filling valve, alternative systems and solutions for the sanitation and rinsing of containers and closures in respect of the product filled

- Secondary packaging consueling

Filling & Packaging helps You to choose the most effective and attractive secondary packaging solutions functionally with Your product, market nice and distribution channels with attention to cost effectiveness and market targets. We focus engineering optimizing environmental impact of waste and utilities

- Labelling and food safety counseling

New directives from national governments, marketing policies and international standards for food safety organizations require a strong attention on labeling and general dressing of the packages. Filling and packaging helps You moving in the wide range of solutions and technologies for the easiest and adequate choice.

- Primary packaging

- Flexibility :

- Multiple containers layout design

Little medium and big packaging plant efficiency depends strongly from the capability to shift from one container to another. Filling & Packaging can offer plants able to perform filling, packaging, labeling and transportation of glass, Pet, glass and Pet, cans and multiple secondary packaging opportunities. Change format parts are engineered for fast change over and, possibly, without any tool use.- Existing machineries and used machineries integration

Filling & Packaging help You to limit investments by integrating existing packaging machineries and others constructors parts used or new. - Quality:

- Suitable filling technology evaluation on local environmental and product needs

Climate, local conditions and utilities availability, restricted areas and controlled air needs influences the layout and choice of technologies. Our world wide experience is at Your service to minimize investment and maximize quality.- Hygiene and facilities, line and machine engineering to improve organoleptic and shelf time performances

Different optional and devices can optimize the quality of the product or the general appearance of your packaging. Filling & Packaging is able to fix up the right tool in the right place to improve Your quality parameters and risk management - Cost effectiveness:

- Running line crew evaluation

Our plant layouts are engineered and parameterized to personnel safety and working hours optimization- Electricity, steam, CO2, nitrogen and compressed air consumption evaluations and optimisation

On the base of the product filled and packed Filling & Packaging can propose the right technologies to save utilities, increase profitability and help environment- Existing structures and packaging machineries adaptation

Filling & Packaging help You to limit investments by integrating existing packaging machineries and others constructors parts used or new. Filling & Packaging can also supply used packaging machineries for Your capex optimization

- Products, container and packaging consulting:

-

Turnkey packaging plant construction, delivery and services

- Credit and financing

Filling & Packaging finance department keeps optimal relationships with most of the international banks. Our finance experts can help You to prepare the necessary documentation to finance Your capital expenditures- Machineries production

Filling & Packaging produces filling monoblocks, conveyors and palletizing and depalletizing systems designed on the base of the customer needs with a special focus on special quality applications- Machineries construction follow-up and tests at manufacturer site

Time schedules and respect of contract characteristics are strongly pursued by our technical and purchase department in full respect of due time an quality.- Packaging line technical documentation and emergency spare parts advices

Filling & Packaging experience can provide You with the most efficient list of emergency spare part and 1000, 2000 working hours wear and tear spare parts. Our organization pay special attention to the collection and delivery of multi-language technical documentation- Line components packing and transport

Our shipping department is well trained and experienced to protect the packaging machineries for the international and intercontinental transports and grant a timely delivery.- Custom clearance assistance and documental credit management

Filling & Packaging is at Your side during the clearance of the good assisting with order and clear documentation for the management of the bank financing- Erection, installation, commissioning and training:

Our supervisors are managers with a broad technical experience, pro-active and good communicators accustomed to working with the local workforce. All technicians are regularly trained on site and at our premises with the latest developments and technologies.

Commissioning and training are as much important as machineries: our commitment it to provide our customers’ crew with the skills to run professionally our turnkey plants and all the machines tested and the whole line productivity confirmed.

-

After sale services

- Spare parts and technical intervention and Remote Assistance

Filling & Packaging is always on their toes ready to intervene in order to supply spare parts as soon as possible. We are ready to assist for our own plants and for the one you might have bought from others.

For your comfort and safety we also install remote monitoring tools working on line.

- Programmed maintenance and Equipment audits

Filling & Packaging offers sets of scheduled interventions for monitoring your machineries.

We also offer preventive maintenance interventions and the management of your stockings for urgent or strategic spare parts supply

-

Overhauling, plant optimization and management

- New products and containers implementation

Filling & Packaging helps You to maintain Your competitiveness by assuring a continuous state of the art offer on technologies and innovations from the world of packaging machineries and materials. Our technical department and engineers will take car of the options to implement new product and container dressing to implement the flexibility of Your line.

- Machine and line overhauling

Our equipments are investments that can last for a long and efficient run. Nevertheless Filling & Packaging can manage and organize overhauling of machines and complete packaging plants to restore efficiency and quality of the production- Data management and analysis

Do not hesitate to contact out technical personnel to obtain counseling about improvements of productivity efficiency or quality issues. - New products and containers implementation