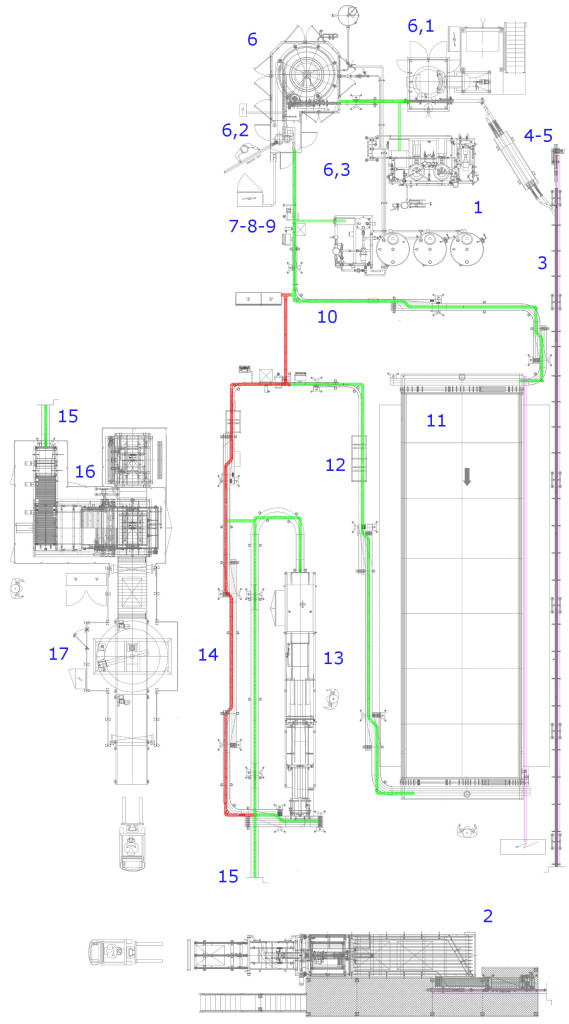

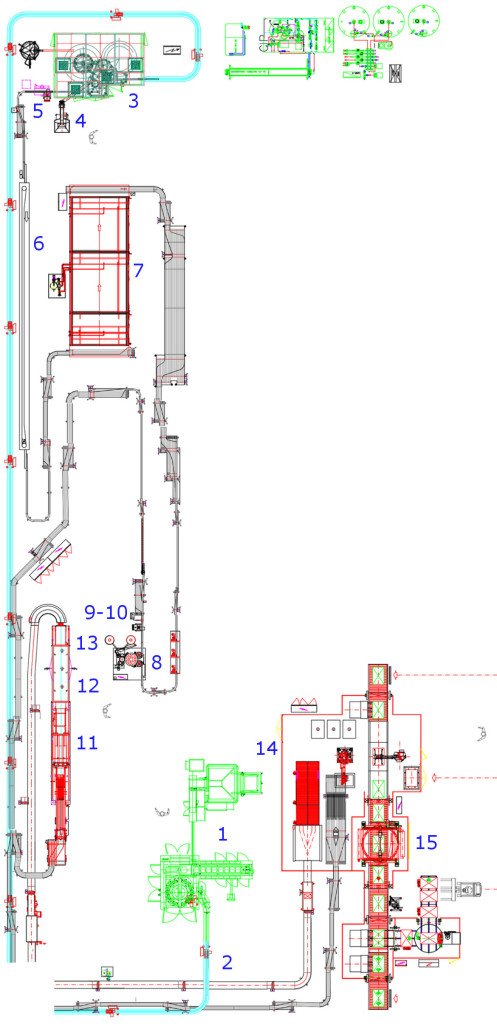

| Position | Machinery | Model |

| 001 | Blow-moulder | Blow-moulder complete of preform feeder and cooler |

| 002 | Rope conveyors | Filling & Packaging conveyors systems |

| 003 | Filler monoblock and CIP clean in place system | F&P M UNICA HOT FILL

50 Rinsing grippers

50 Filling valves

10 Capping heads |

| 004 | Cap Elevator | Mechanical cap elevator for plastic screw caps |

| 005 | Inspection and control | Cap and level control with discharge |

| 006 | Cap and bottle neck sterilizer | Filling & Packaging tilting conveyor sterilizer |

| 007 | Cooling tunnel | Filling & Packaging pasteurizer cooler tunnel |

| 008 | Labeler | Hot melt labeling machine 18 heads |

| 009 | Inspector and controls | Label control |

| 010 | Marker | Ink Jet Marker 2-3 lines |

| 011 | Shrink-wrapper | Shrink-wrapper 60 packs per minute |

| 012 | Handle applicator | Automatic handle applicator |

| 013 | Labeller | Self adhesive label applicator |

| 012 | X ray inspector | Handle applicator for transparent or printed handles |

| 013 | Stretch-wrapper | F&P M. Estensa |

| 014 | Palletizing island | F&P M. Palletizing technology:

rotating ring stretchwrapper,

pallet multi labels applicator,

trays forming, and

transports of bottles, packs and pallets |

| 015 | Palletizer | F&P M. PA4B |

| E | Power and electrical controls | Line Power Board, Conveyors Power Board, Cables |